Nissan Altima Caliper Bracket Bolt Torque: Let’s Find It Out

Thankfully, accurately achieving the manufacturer torque spec is straightforward when adhering to service manual guidelines.

For most Altima models from 2002 to the present, you’ll need a torque wrench capable of approximately 80 to 100 lb-ft with an angle gauge, which is highly ideal.

Always begin by referencing your specific generation and engine Altima factory service manual through resources like Alldata or Identifix to confirm the exact torque specs, sequence, and angle torque values.

Table of Contents

Step-by-Step Points for Torquing the Caliper Bracket Bolts on a Nissan Altima

Confirm the Vehicle Specifications

Verify the model year and the engine type of your Altima to determine the proper factory torque spec for the caliper bracket bolts.

Consult your owner’s manual or a database like Alldata or Identifix.

Common torque values are:

- 2002-2006 Altima – 84 lb-ft

- 2007-2012 Altima – 98 lb-ft

- 2013-present Altima – 89 lb-ft

However, check the year/make/model to confirm the exact spec for your vehicle.

Inspect the Bracket Bolts and Brackets

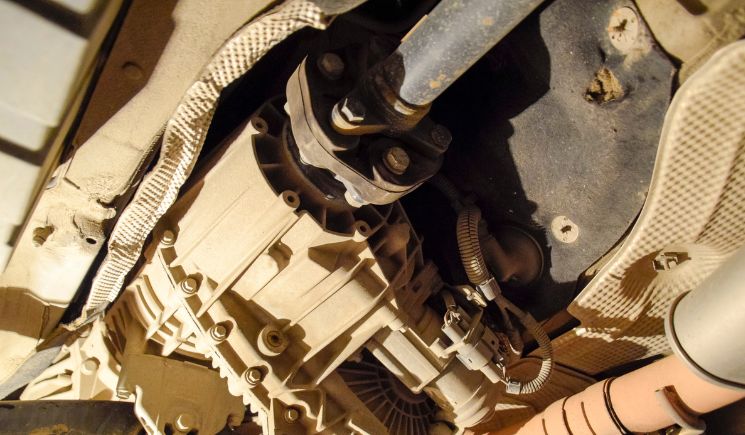

- Raise the vehicle safely by using a proper jack, and jack stands.

- Then, remove the brake caliper assembly.

- Clean away any debris or corrosion on the caliper bracket and mounting bolts by using a stiff brush or a brake parts cleaner spray.

- Inspect the condition of brackets and rubber insulators. They should not be out of shape or overly under bad condition.

- Threads and bolt shafts should be clean with no cracks. Replace if critical wear is visible.

Apply Threadlocker

- Apply medium-strength thread-locking fluid like Loctite 243 to the threads of the caliper bracket bolts before reinstalling.

- This ensures bolts resist vibrational loosening. In addition to that, it also prevents contact with the brake pads/rotors.

Torque Bolts in Sequence

- Reinstall the caliper bracket and bolts by first torquing them by hand-tight.

- Follow a criss-cross sequence; this is because torque bolts to factory specs with an adequately calibrated inch-pound torque wrench is vital.

- Continue the sequence until you reach the specified torque value without going over. Do not skip the final torque verification.

Confirm the Proper Torque with an Angle Gauge

- Use an angle torque meter on bolt head to check the final torque application angle.

- The angle should align with factory specifications if the torque reading is correct.

- If there is no angle spec, bolts should rotate less than 10 degrees or 1/36 of a turn when the final torque is applied.

Importance of the Proper Torque

- Without the precisely calibrated clamping force created by torquing the bracket bolts to specification, the forces generated when stopping the vehicle can pull the caliper out of alignment.

- This leads to uneven pad wear, brake noise, vibration through the pedal or steering wheel, and reduced effectiveness.

- In a worst-case scenario, severely loose bolts can allow the bracket to detach altogether by causing a total loss of braking power.

- That leads to using a recently calibrated torque wrench paired with the factory procedure, which is absolutely mandatory during the brake service.

- Fortunately, Nissan includes not only the torque values but also the proper techniques within their repair manuals.

- Combining the specified torque with the prescribed tightening sequence and angle tolerance.

- It will be checked by using an angle meter, which guarantees a secure installation.

- Taking these extra steps when servicing your Altima’s brake hardware protects your safety and prevents avoidable comeback repairs down the road.

Frequently Asked Questions About Nissan Altima Caliper Bracket Bolt Torque

Q: How soon can the car be driven after torquing the bolts?

A: Allow at least 2 hours for the thread locker to fully cure before road testing. This ensures the caliper bracket integrity.

Q: What happens if the bolts are under-torqued?

A: Under-torqued caliper bracket bolts can loosen over time by leading to brake vibration, uneven pad wear, noise, reduced stopping power, and possibly brake failure as well.